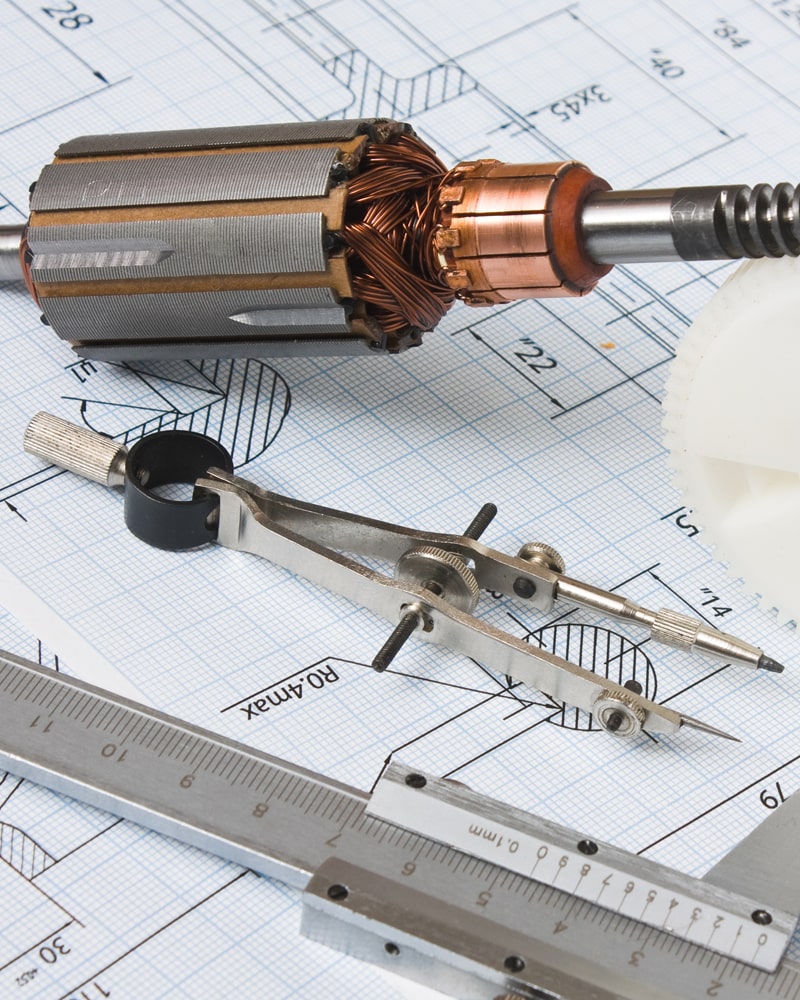

In the very beginning, we disassembled the motor (Motor Tear Down) and created a single part overview of the electric motor. During our single part analysis, we assigned a manufacturing process to each motor component and we have evaluated the costs with our Promotex Should Costing Tool for electric motors.

In the second step, the motor assembly steps have been deviated from the motor structure and the supplier production concept has been created. With support from our Promotex Database and our manufacturing knowledge we have calculated the specific investments and cycle times of the motor production line.

At the end we have created our Promotex Electric Motor Cost Model, which includes not only the single motor components, the manufacturing process and the overhead costs but has also a sensitivity analysis concerning raw material price developments and other inflation cost drivers.

During our analysis, we have further on identified several technical optimization ideas, which could reduce the motor cost by 10%. Together with our customer, we have kicked off a separate project to realize those optimizations within a technical change process.