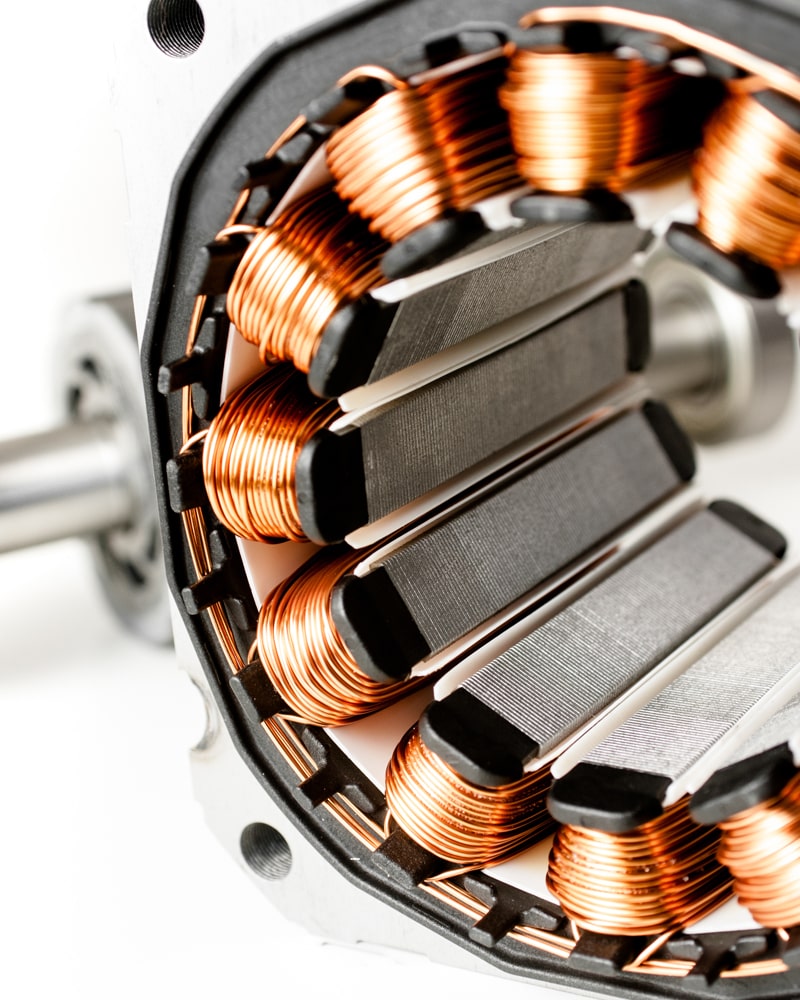

Together with our customer, we are working on an optimization project for three years to set up a competitive motor model kit.

Base for the optimization of the current developed electric motor is our tear down and should cost approach. We have already optimized 16 out of 40 single components together with the engineering department. With some preferred component suppliers we have made optimization workshops throughout the complete value chain. Especially with manual operation in best cost countries, we have identified optimization potentials which are partially already realized in the product and process development process.

In the second step, the planned motor assembly concept has been analyzed and the first improvements have been defined. Pending on the market success of the new product, different production concepts have been created.

Within the next two years, the other components will be analyzed, the production concept will be finalized and a Motor CO2 model will be created.